Our products

A solution for every lift

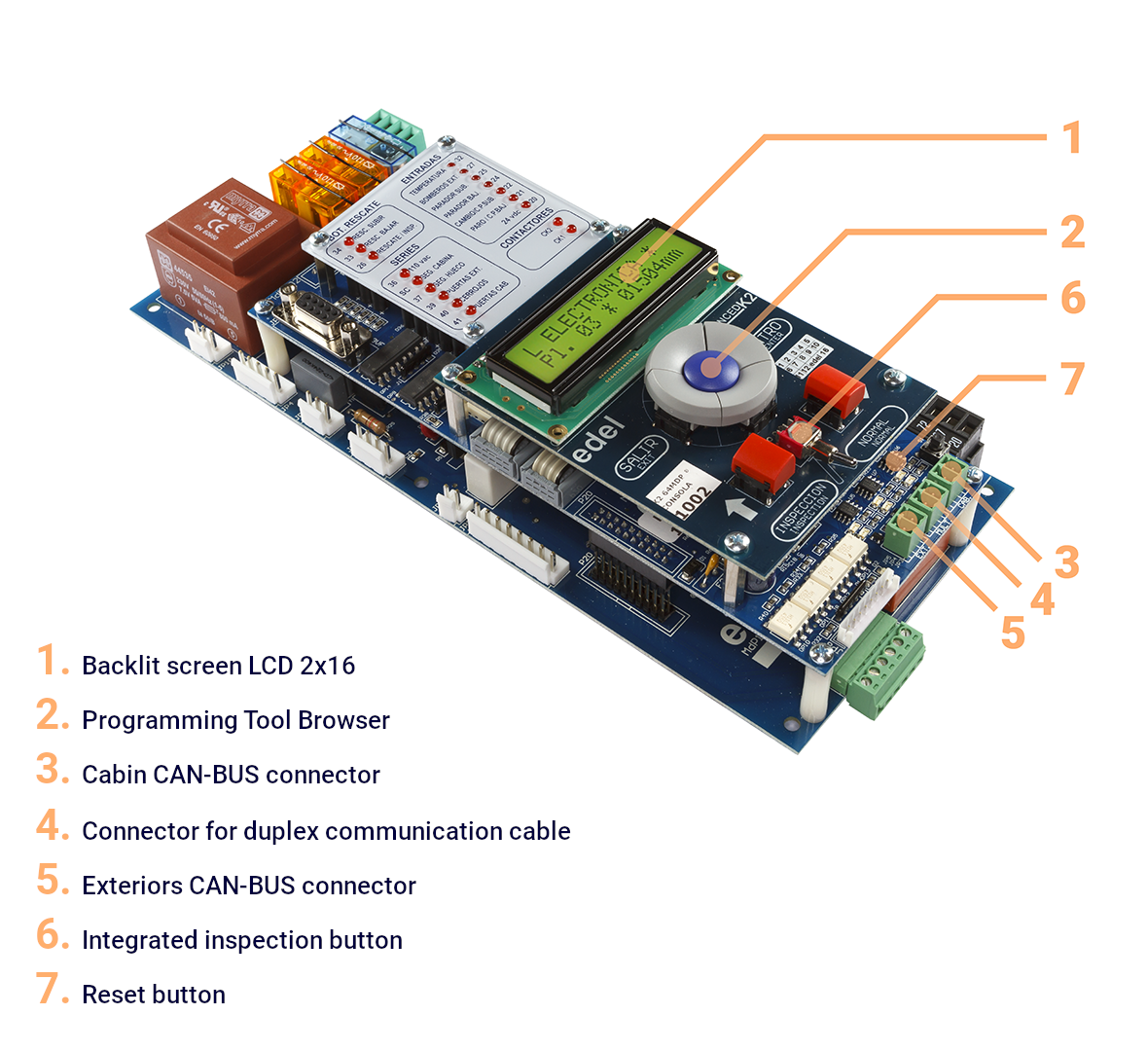

Advanced Series

A world of possibilities

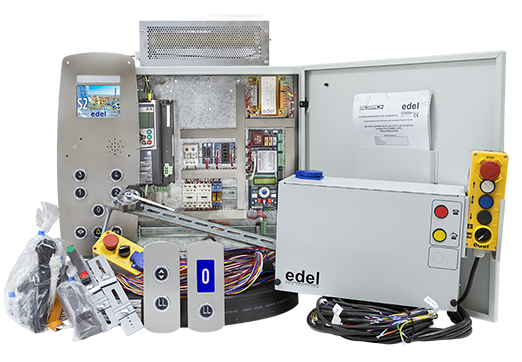

Advanced complete installation

i

Advanced inspection box

Optional elements

Packaging

CAN bus external communication

Ziehl-Abegg inverters

Labelled cable groups with Plug&Play connectors

Installation with standard EN 81-20/50

Plug&Play cable groups.

edel Technical Services

Customisation of button panels

Customised configuration

Standards

We manufacture according to the requirements of the building and adapt to any standards and regulations.

Aware that every building has its own special characteristics, our manufacturing processes are extremely versatile. We adapt every last detail of our product to the lift, carrying out individual installations, always in accordance with the wide variety of regulations that our sector demands.

- All our products are manufactured according to directives 2014/33/EU, 2014/30/EU, 2014/35/EU.

- Hoses and wiring according to standards UNE EN-50214 and UNE EN-60332-1-2

- European Standards UNE EN 81-20 and UNE EN 81-50

- EN 81-21:2018

EN 81-28:2018+AC:2019

EN 81-70:2018

EN 81-71:2018+AC:2019

EN 81-72:2015

EN 81-73:2016 - Standards for South America.

- Shaft and Clearance Standards.

- Firefighting regulations.

- ATEX regulations for programmable electrical installations applicable to explosive environments, manufacturing each part manually, certifying all the elements according to the requirements of the standard.

- EN 81-76